Essential Upkeep: Tips for Extending the Life-span of Komatsu Undercarriage Parts

Essential Upkeep: Tips for Extending the Life-span of Komatsu Undercarriage Parts

Blog Article

Trick Components: Undercarriage Components for Heavy Equipment

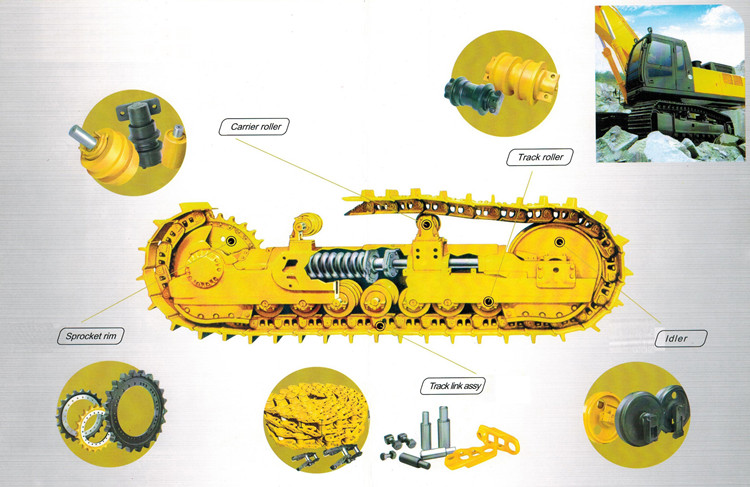

In the world of heavy machinery, the undercarriage acts as a crucial structure that makes sure the smooth operation and longevity of the equipment. Key parts such as track footwear, rollers, idlers, gears, and track chains play a crucial role in the capability and performance of these massive devices. Each aspect adds to the overall security, grip, and longevity of the heavy machinery, making them indispensable for optimum operation. Understanding the intricate interplay of these undercarriage components is vital for upkeep and operational effectiveness, prompting a better exam of their relevance in the grand scheme of hefty tools performance.

Track Shoes

Track shoes play a critical function in the efficiency and longevity of heavy equipment's undercarriage system. Track footwear come in different layouts and materials to suit different operating conditions and terrains.

The layout of track footwear is engineered to give ideal ground call, lowering slippage and boosting the machine's capability to browse tough terrains (komatsu undercarriage parts). Appropriate maintenance and routine evaluation of track shoes are needed to avoid premature wear and make certain the undercarriage system's durability. Any type of signs of wear, such as unequal wear patterns or extreme damages, ought to be dealt with promptly to avoid expensive repair services and downtime

Rollers

To enhance toughness and performance, rollers are normally constructed from top notch products like forged steel, using resistance to tear and use under hefty lots and rough working conditions. Correct lubrication is essential to decrease friction in between the rollers and track footwear, prolonging the life-span of both parts. Normal examination and upkeep of rollers are necessary to avoid early wear and prospective break downs, ensuring the continuous operation of heavy equipment.

Idlers

Idlers play an essential function in the undercarriage system of hefty equipment, working as crucial components for maintaining proper track chain stress and ensuring optimum maker efficiency. Idlers are accountable for leading the track chain and supporting the weight of the devices. These cylindrical rollers are tactically placed along the track structure to disperse the device's weight uniformly, reduce resonance, and boost security throughout operation.

Properly functioning idlers assist avoid premature endure the track chain and various other undercarriage parts, inevitably expanding the life expectancy of the equipment. They likewise add to fuel performance by lowering rolling resistance and lessening the energy required to move the tools. Normal assessment and maintenance of idlers are critical to detect any type of indications of wear, misalignment, or damage that might cause efficiency concerns or downtime.

Sprockets

Playing an essential role in the undercarriage system of hefty machinery, sprockets are essential elements responsible for moving power from the equipment to the track chain. Gears feature toothed wheels or equipments that mesh with the links of the track chain, enabling the equipment to push forward or backward. By understanding the significance of gears in the undercarriage system, drivers and upkeep employees can properly handle these parts to enhance the general performance and integrity of hefty equipment.

Track Chains

An indispensable part of the undercarriage system in hefty machinery, track chains play an important duty in leading the movement find here and sustaining of the tools. Track chains are durable steel chains that connect the drive sprocket to the wheels or tracks of the heavy equipment (komatsu undercarriage parts). These chains are designed to sustain immense stress, wear, and stress while making sure smooth and reliable procedure of the equipment

Track chains are composed of specific web links that are connected by pins and bushings. The design of track chains is vital as it directly influences the overall efficiency and durability of the hefty machinery. Proper maintenance of track chains is vital to prevent early wear, decrease downtime, and prolong the lifespan of the tools.

Regular examinations, lubrication, and changes are needed to maintain track chains in optimal condition. Failure to maintain track chains can lead to boosted functional prices due to regular substitutes and repair work. Investing in premium track chains and sticking to a stringent upkeep schedule is vital to optimizing the performance and long life of heavy machinery.

Final Thought

Finally, the vital parts for heavy equipment undercarriage parts consist of track footwear, rollers, idlers, sprockets, and track chains. These components are necessary for the proper performance and operation of heavy equipment, providing traction, assistance, and security. komatsu undercarriage parts. It is important for operators and maintenance employees to consistently inspect and maintain these elements to make sure the security and performance of the equipment

Trick parts such as track footwear, rollers, idlers, sprockets, and track chains play a crucial function in the performance webpage and performance of these substantial devices. Provider rollers assist in supporting the weight of the great post to read equipment, while track rollers assist distribute the lots and make sure smooth track footwear expression. Idlers act as a tensioning device for the track chain, maintaining proper track stress for optimal efficiency.

Track chains are durable metal chains that connect the drive gear to the wheels or tracks of the heavy machinery.In conclusion, the vital components for heavy equipment undercarriage components consist of track shoes, rollers, idlers, sprockets, and track chains.

Report this page